Engine Pictures

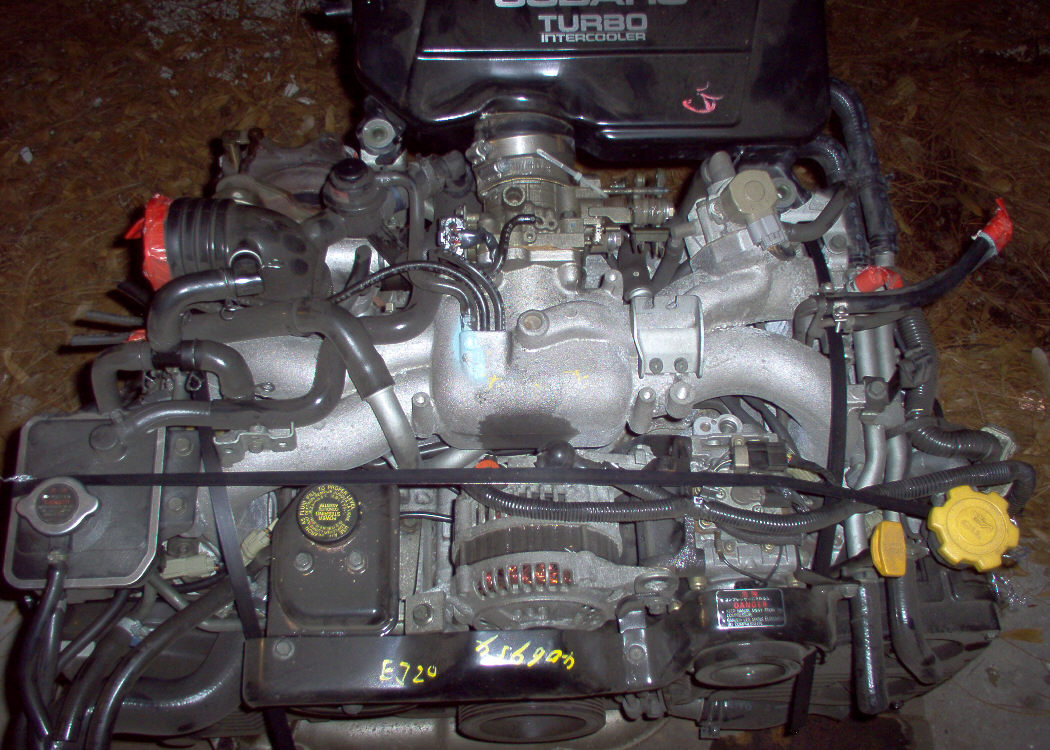

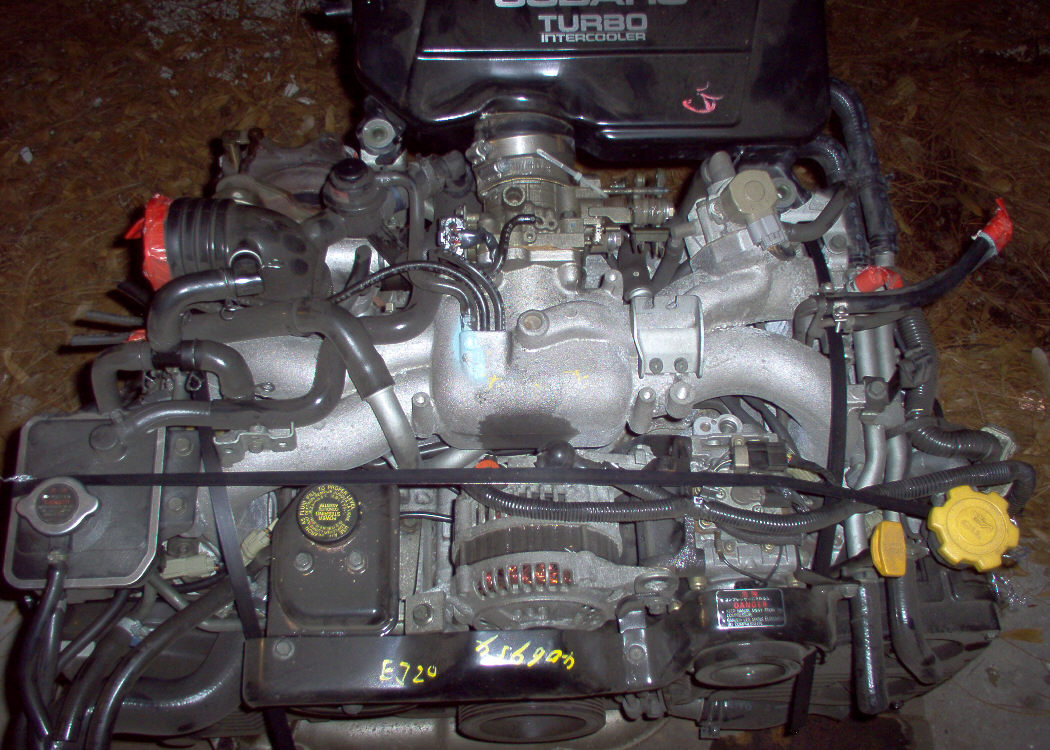

I decided to go with a EJ20T engine from an 89-94 Japanese Subaru Legacy. From what I understand this motor should make 280chp or so with the Megasquirt ECU. After shipping the engine cost me $960 from http://www.japaneseusedengines.com/ I don't think you can beat the hp per dollar that you get from these motors. With a set of pistons this can handle 500+hp. They already come with forged crank and rods. Plus this is a dual over head cam with coil on plug ignition. Best of all, it resembles the original flat 4 motor that this car came with. It won't throw the balance off like a V8 will.

Top View, Note the water-to-air intercooler. I plan on using it for now but will eventually upgrade to a larger water-to-air.

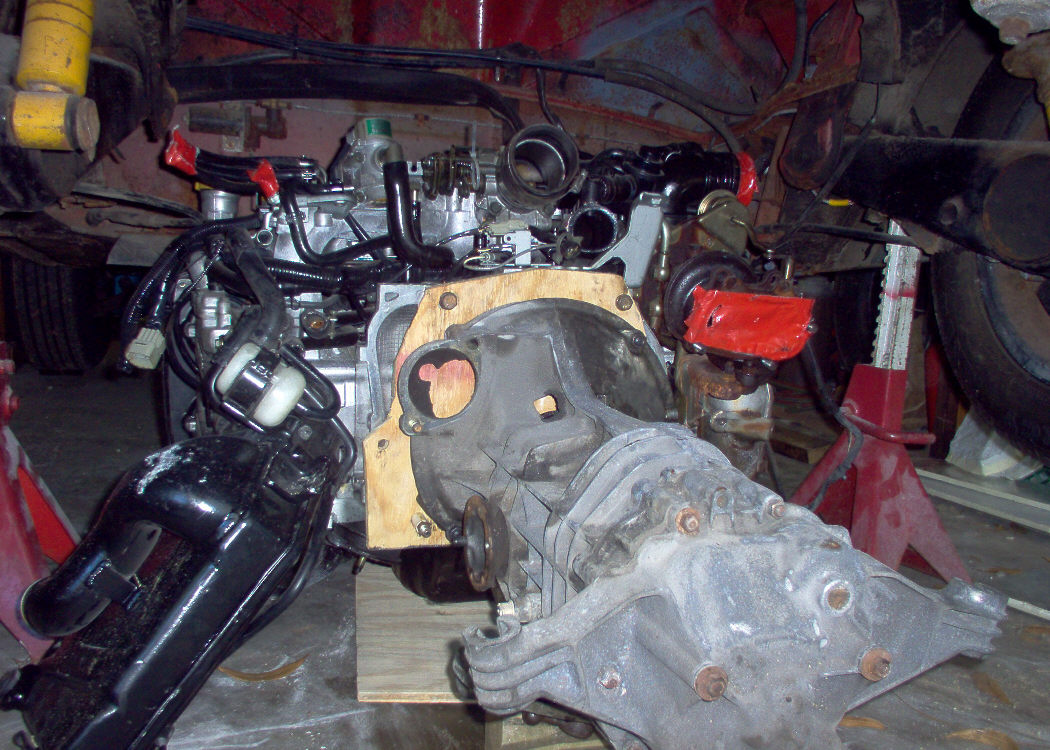

Kennedy Engineering is building the adapter plate. Unfortunately it is going to take 5 weeks. I have built this plywood adapter to mock up the transaxle and engine so I can build the mounts.

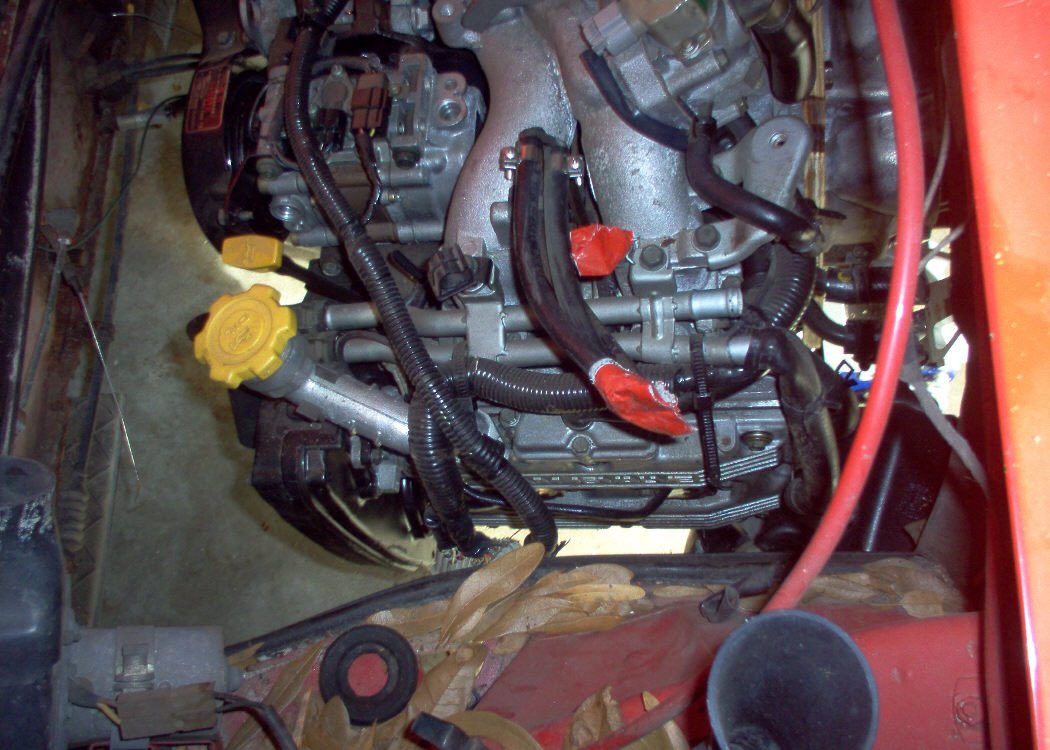

Here is the major issue w/ this swap. The turbo will not clear the trunk without cutting. I plan on relocating the transaxle mounts app 4" forward to give as much clearance as possible. It doesn't look like the turbo will clear w/o cutting the trunk though. Renegade says their kit does not require cutting but since they won't provide a single detail about their product I'm not sure if I trust them.

Another issue, the throttle body points directly into the trunk pan. It will take either some more cutting or some creative pipe work to make this work. The manifold can supposedly be turned around to point the other way but I think I'll run into the same problem w/ the firewall.

Here is a shot of the clearance between the motor and the sides. Its about 2" on each side. I will be completing the motor mounts and transaxle relocation brackets w/i the next week. I'll try to get some pics up asap.

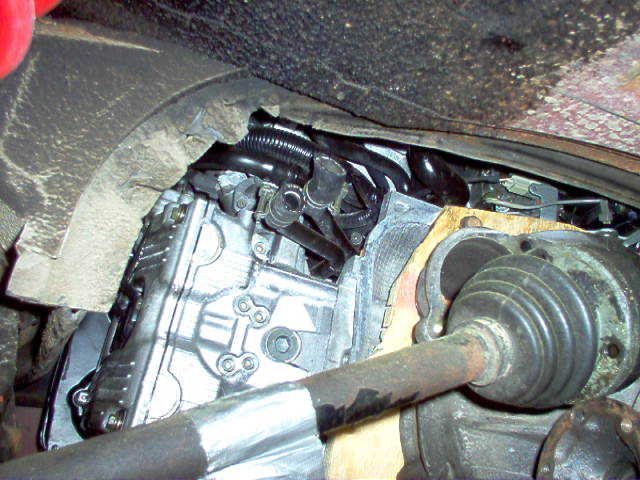

All pictures from here down are with the transaxle relocation mounts in place. This is pretty much where she's gonna sit.

There are actually no clearance issues on the driver side of the motor.

This is a good shot of the exhaust outlet of the turbo. As you can see it goes directly into the trunk pan. I am definitely going to have to cut to make a downpipe fit.

Another shot of the turbo exhaust outlet.

Just got the adapter plate and flywheel in from Kennedy Engineering. These are some really nice pieces. I would definitely recommend ordering this package from them. I have included dimensions just in case any of you need to build a wood adapter like me.

Hardware that came with the package. They used grade 8 and grade 10 bolts.

Here's the flywheel. It's heavy but I'm sure I'll never have to replace it.

Engine side of the flywheel.

Here are some pictures of the motor mount. I'm sure I overbuilt it, but I'm not an engineer. I used 2" box steel with 1/4" walls. The plates are also 1/4". This is actually three pieces that bolt together. I did it this way, otherwise the arms would not be able to slide off the engine mounts. I have had the motor sitting on this already and it seems like it will work nicely. You'll note that the engine mount is still attached to one of the arms. The bolt stripped out of the rubber part so I am leaving it there for mock up purposes until I replace them w/ solid mounts.